Rapid prototyping is a software

development method in which things get instantly built using SFF or solid

freeform fabrication. A rapid prototyping or

working model can be constructed and tested for usefulness, speed, and output.

In the prototype, the new features or ideas can illustrate, and early consumer

feedback on the product can be gathered.

Collect

more accurate requirements:

Increased project costs get ascribed

to revisions caused by insufficient requirements. Because many people find it

difficult to conceptualise a product before seeing it, traditional

requirement-collecting methods such as interviews and focus groups can fall

short, show the functionality and help solidify criteria for the final design

by creating a functioning rapid prototyping.

Discovery

of Errors:

The advantage of prototyping is that

it enables you to discover mistakes early in the manufacturing process. As a

result, you have a better chance of rectifying these errors and making the

required changes. It allows the designer to alter the product before the errors

become expensive or unmanageable. Product flaws can be detrimental in any

business, but perhaps more so in the medical industry, where they are more

likely to cause injuries or fatalities, resulting in litigation and recalls.

Simply put, it is better to perform comprehensive design testing early rather

than later. Rapid prototyping can assist you in identifying issues during the

early phases.

Ideas

for Flexible Prototyping:

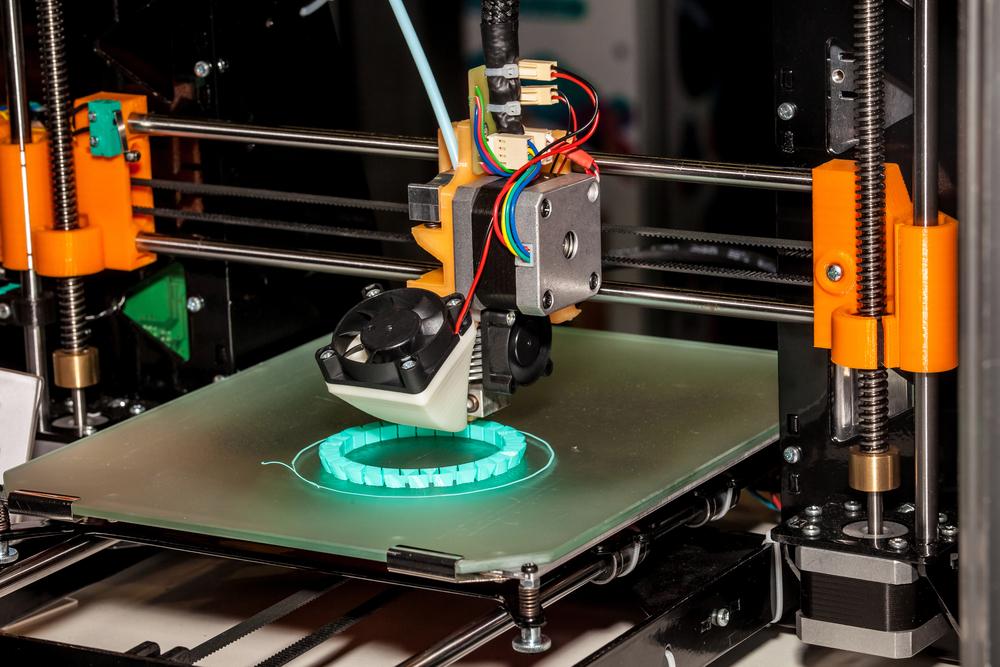

Engineers try a variety of intricate

designs to arrive at the ideal prototype. It was an expensive and

time-consuming task using conventional CNC machining techniques. Engineers can

use rapid prototyping to create and evaluate multiple prototypes without

breaking the budget. Engineers can now use 3D printing to create components

that would have been difficult to generate using traditional sheet metal

manufacturing or CNC machining. Furthermore, 3D-printed parts do not require

specialist tools to create a prototype.

Including

Invention:

Instead of viewing a product through

a computer, it enables you to engage with it and grasp the look and feel of the

design. Rapid prototyping expands possibilities by eliminating the constraints

of conventional testing. Designers can now build complicated forms and surfaces

that appear to get unachievable with traditional prototyping.

Attempt

Several Styles:

Because methods like SLS rapid

prototyping are quick but inexpensive, you can create multiple prototypes and

evaluate them side by side. It is comfortable if you want to demonstrate to

your customer several ideas, for example. It is both inexpensive and fast, and

you can make sample changes based on feedback, which will get produced in 3D

without delay. Furthermore, you will be able to evaluate various hues, shapes,

and forms in a hands-on way that will easily outperform any 2D design

documents.

Improved

and expanded user involvement:

Most customers want to feel as

though they are engaged in all aspects of their endeavour. Prototyping

necessitates user participation and allows them to see and engage with a

functioning model of their project. Customers can provide instant input,

request project changes, and modify model specs using prototypes. Most

significantly, prototyping aids in the elimination of errors and

miscommunications during the development process.